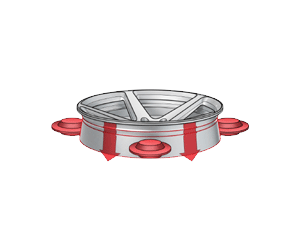

VD45X SPIN FORGED

The VD41X, part of our Spin Forged Series, has a sleek concave profile and angles to give it a defining image. Specifically designed for C5, C6, C7, C8 Corvettes. It comes in a standard and widebody options.

Starting at $439ea

SIZES

19x9.5 / 20x11 Standard Corvette

19x10 / 20x12 Grand Sport & Z06

FINISHES

Gloss Titanium / Brushed Face

Gloss Black

BOLT PATTERNS

5x120.65

WEIGHTS

19" ~19-21 lbs

20" ~22-24 lbs

OFFSET RANGE

+30mm TO +73mm

*max range varies by size

What is Spin Forged?

IT'S ALL ABOUT INNOVATION

Rotary Forged or Spin Forged is the technology of Flow Forming a wheel and is one of the most innovative manufacturing processes to enter the wheel industry. This complex process involves the application of heat and pressure to the inner barrel of the wheel, stretching and compressing the aluminum, which increases tensile strength of the barrel. This development shares similar properties to those found in the forging method.

The final product is lighter, stronger and has improved shock resistance as well as an increased load capacity over regular cast wheels. The major difference between cast and flow formed wheels is in the thickness of the wheel barrel. The flow forming process increases the strength of the aluminum allowing the barrel to be made much thinner and lighter than a regular cast wheel.

STEP 1

A specially designed aluminum cast is created with the barrel ready to be Flow Formed.

STEP 2

The wheel now spins at a high rate as it gets heated to allow for the stretching of the material.

STEP 3

Once heated, the rollers press onto the barrel in a downward motion to the required width of the wheel.

STEP 4

As this process finishes, the aluminum strengthens giving the wheel higher impact tolerance.

INVENTORY

SIZE | PCD | ET | FINISH | HUB | QTY | SKU |

|---|---|---|---|---|---|---|

| 19X10 | 5X4.75 | 30 | Gloss Black | 70.3 | 8 | V45X1910CP305N70GB |

| 19X10 | 5X4.75 | 30 | Gloss Titanium Brushed Face | 70.3 | 14 | V45X1910CP305N70TIU |

| 19X9.5 | 5X4.75 | 53 | Gloss Black | 70.3 | 20 | V45X1995SP535N70GB |

| 19X9.5 | 5X4.75 | 53 | Gloss Titanium Brushed Face | 70.3 | 10 | V45X1995SP535N70TIU |

| 20X11 | 5X4.75 | 73 | Gloss Black | 70.3 | 20 | V45X2011SP735N70GB |

| 20X11 | 5X4.75 | 73 | Gloss Titanium Brushed Face | 70.3 | 12 | V45X2011SP735N70TIU |

| 20X12 | 5X4.75 | 50 | Gloss Black | 70.3 | 8 | V45X2012CP505N70GB |

| 20X12 | 5X4.75 | 50 | Gloss Titanium Brushed Face | 70.3 | 12 | V45X2012CP505N70TIU |